High copper wire losses? Diggers tubing machine's "wire slimming technique" saves you enough in a year to buy a Wuling Hongguang!

Release time:

2025-04-17

Still worried about excessive waste from copper wire cutting? And feeling the pinch on costs?

Still comparing prices online and struggling to find the most cost-effective equipment?

The truth is: Every 1mm reduction in wire cutting length can save you more profit than you imagine!

Today, Diger uses cutting-edge technology to help you 'eliminate waste'!

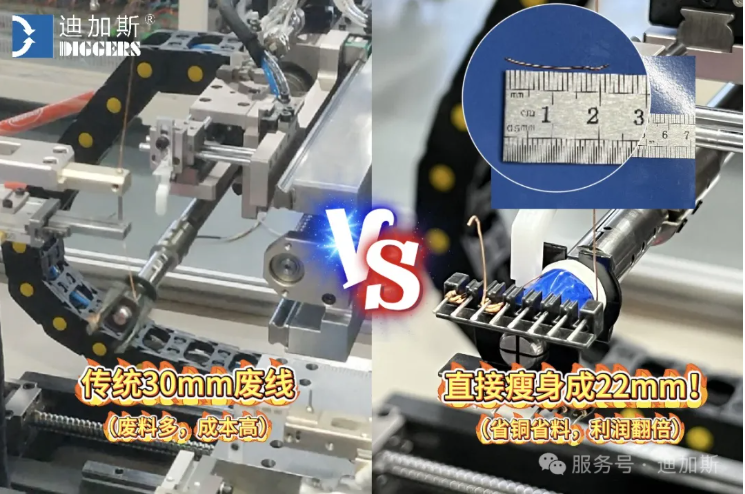

Traditional Cutting vs. Diger Precision Blade Technology

❌ Traditional wire cutting

Waste wire length 30mm → High copper material consumption, high cost pressure, waste piling up like a mountain!

✅ Diger servo cutting

Waste wire reduced to 22mm → 8mm saved per cut, 26% waste reduction, easily saving back the equipment cost in a year!

► Save 8mm of copper wire per cut, saving annual costs in mass production ≈ one Wuling Hongguang!

Servo precise control knife with 0.01mm error

► No wire jams, no waste, maximum efficiency without compromise!

0.1~0.7mm wire diameter universal

► No debugging required for wire change, zero downtime!

Related News

National Service Hotline

No.7, Science and Technology 1st Road, Gangwan Avenue, Tangjiawan Town, High-tech Zone, Xiangzhou District, Zhuhai City, Guangdong Province

SEOTechnical Support:www.300.cn

SAF Coolest v1.2 设置面板 ZBUSX-ZWDY-NVAFE-ZAD

无数据提示

Sorry, the current column has no content for the time being.!

You can view other columns or returnHome Page

公众号

公众号